We love exciting tasks - like the one of making a first-class robot with an unbeatable price-performance ratio possible together with fruitcore robotics.

Optimizing drive concepts and adapting them to customer needs ... that's our day-to-day business.

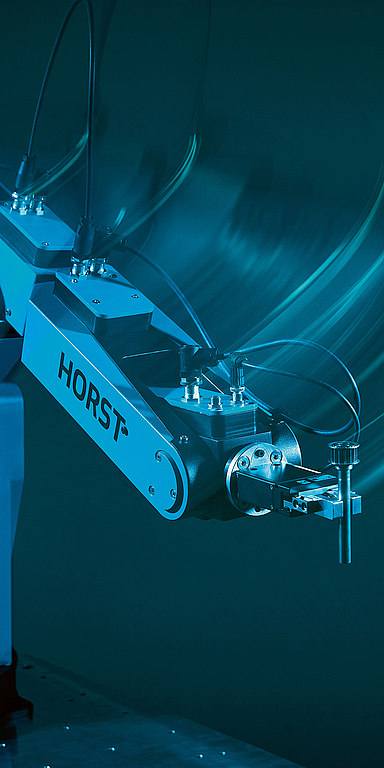

Our HORST project, for example, shows that we are really good at this.

How did we become involved with HORST?

"We were looking for a suitable provider of planetary gearboxes that were exactly right for our system or can be adapted accordingly – and we also wanted them to be manufactured in Germany", explains M. Eng. Manuel Frey. He is head of development at fruitcore robotics GmbH. And with HORST, the Constance-based company has set itself high goals.

HORST had to be easy to operate, powerful, compact, optimally mobile and flexible - and convince customers with its price/performance ratio. This would make HORST "also interesting for small companies". And certainly for medium-sized and large companies", states M. Eng. Manuel Frey. To make this work, many components have been optimized for HORST.

HORST and Neugart – a perfect match

The development goal for HORST: An optimal ratio of reach and payload. This is made possible thanks to a novel concept for the drive: use of a four-bar linkage. This replaces the expensive shaft or cycloid gearing usually used.

During development, the engineers at fruitcore robotics realized that they would need to integrate additional gears on the axes to achieve HORST's desired performance. This is exactly where we came in with our gearbox knowledge.

Our perfect solution

We were allowed to accompany fruitcore robotics in an advisory and design capacity. The final result: Single-stage planetary gearboxes that we adapted for use in HORST. The decisive criterion we had to meet in the process for development manager Frey and his colleagues:

- The gearboxes had to operate with high precision and guarantee minimal torsional backlash.

- The same was true for the fatigue strength of the gearboxes.

- We were able to achieve both because we designed our gearboxes for fruitcore robotics to operate in the nominal range.

- Thus, precision, fatigue strength and durability are guaranteed in HORST.

Incidentally, a total of four adapted Neugart gearboxes in various sizes are used on the six robot axes. These are not only designed to be particularly robust, but are also especially light, powerful and, thanks to low-friction bearings and optimized lubrication, suitable for the demanding and dynamic load cycles that HORST experiences.

A look into the future

Will HORST stand the test?

In the meantime, fruitcore robotics now offers HORST in different sizes and for different applications. We invite you to learn more about HORST here: https://fruitcore-robotics.com/

"The implementation of the gearboxes went absolutely smoothly. Neugart always reacted to our adaptation requests quickly during the development phase. The data and information in the catalog and the TDF and NCP configuration tools which Neugart provided right from the start were also very useful, and so comprehensive that we were able to start immediately. Of course, technical issues cropped up occasionally, but these were always quickly and easily cleared up with close reciprocal coordination."

M. Eng. Manuel Frey, Head of Development at fruitcore robotics GmbH

Downloads

Would you like to start a project together?

We would be happy to help you!

Neugart Sales Team

Let's stay in touch

Subscribe to our newsletter

Be the first to know about new products, trade shows, training dates and stay up to date.

Subscribe